CASE IN POINT

Packaging for less waste

We changed our packaging for one client that wanted to reduce carbon waste.

All they had to do, was ask.

"Five years on and we’ve built a relationship where they can just ask us anything.

Sustainability, affordability, we’re open to anything that can be done better."

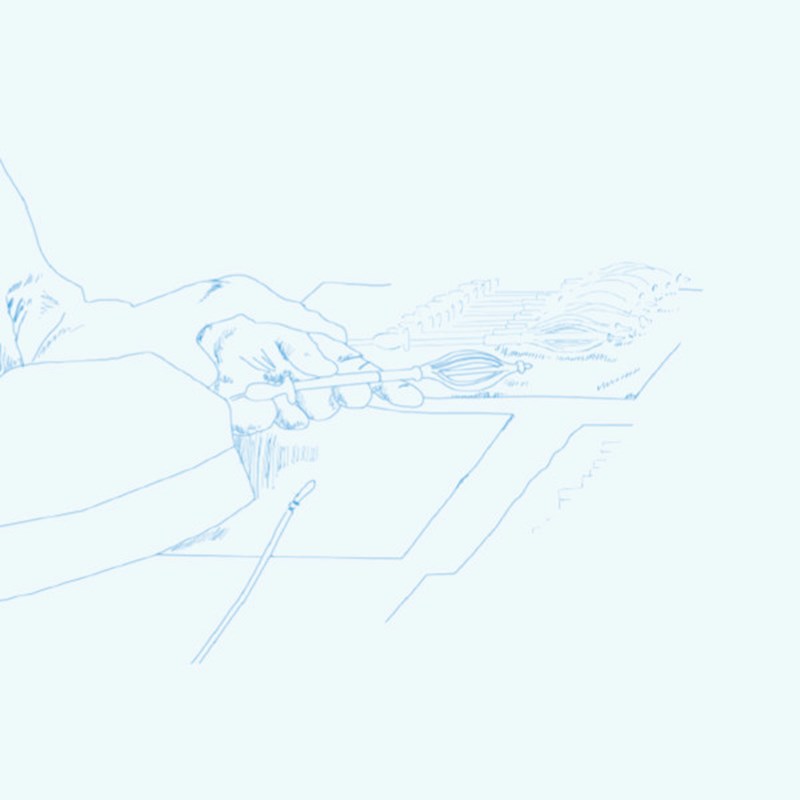

There are small changes we make for our customers, that make a big difference to their business. Like one DHB, who asked if we could reduce the packaging used for their non-woven swabs.

Traditionally our swabs are packaged in sets of two or five. 25 of these are boxed, and then 60 boxes are packaged to send. That’s three layers of packaging. Although these quantities are ideal for smaller practices, the procurement team at this large DHB identified that they were giving wards 50 at a time and waste could be saved.

Now, we supply this DHB with 30 boxes of 50 instead. That’s less waste, less time opening products, and packaging that’s been customised to their particular process. Five years on and we’ve built a relationship where they can just ask us anything. Sustainability, affordability, we’re open to anything that can be done better.

More success stories

Customisation on small runs

Our packs are nothing unique. It's the fact we customize them at low cost, no matter how small the production run.

Switching supplier suddenly

When a DHB got a three-week warning that their sterilisation wraps wouldn’t be supplied, they contacted us for a solution.

Need something specific?

Our supplier relationships mean we can source

and customise products specific to your needs.